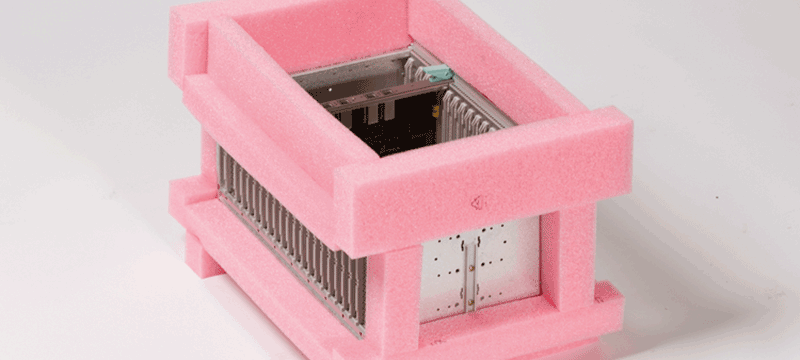

ESD Packaging

Many electrical components, including computer chips, electronic assemblies and circuit boards, can be damaged beyond repair by electrical discharges. Nefab offers several types of ESD protective packaging solutions.

What Nefab offers:

Electrostatic Discharge, ESD, can cause damage or operational disturbances in electronic equipment. Knowing this, and with our expertise, Nefab can provide a suitable ESD packaging solution that is customized to meet specific demands.

A complete range of shielding, conductive, insulating and dissipative products enables Nefab to design a solution that gives the required protection.

Nefab can offer a complete ESD control program, including products for the EPA, grounding products and testing equipment.

ESD Packaging Program

An ESD Program should include the following points, by following the below points damage can be minimized.

- ESD training and instruction

- Handle ESD sensitive (ESDS) products only in an ESD Protected Area (EPA).

- Keep all conductors (including persons) on the same potential.

- Remove all "common" (charge generating) plastics from the EPA.

- Neutralize electrostatic charges on essential insulative materials by using ionization.

- Surround all ESDS with ESD safe packaging materials, except when they are being actively worked on.

Checklist for ESD safe handling

ESD Evaluation

- Assign an ESD coordinator.

- Which components are ESDS (ElectroStatic Discharge Sensitive)?

- Where are ESDS products handled?

- Which processes can cause ESD?

- Where do ESDS products go to after leaving the plant?

- Quantify damage and loss due to ESD.

ESD protection Optimal ESD protection can be achieved by a combination of:

- ESD training and instruction;

- ESD protective products;

- Frequent monitoring of the above.

ESD training and instruction

- Explain why ESD protection is necessary.

- Demonstrate the use of various ESD products.

- Adjust precautions to the practical working circumstances.

- Explain that ESD protection can generate a generous return on investment.

EPA (ESD Protected Area)

- ESD safe worksurface.

- Wrist band with grounding cord.

- Identification EPA (caution sign).

Additional/optional:

- ESD safe floor, in combination with shoe grounders or

- ESD safe footwear.

- ESD safe chairs.

- ESD safe binders and document holders.

- ESD safe garments (gloves, coats, headwear).

- ESD safe tooling.

- ESD safe waste bins.

- Worksurface ionizers.

ESD protective packaging

- Checking of packaging of incoming goods.

- Packaging requirements of the product:

- Product sensitivity electrical properties

- Mechanical properties

- Water Vapour Transmission Rate (WVTR)

- Single use or re-usability

Over the years, Nefab has delivered solutions for many applications, often in combination with corrosion protection.

Benefits of ESD protection:

- Ensures your products arrive safely

- Completely customizable

- Wide range of products to choose from

More information about ESD can be found here: